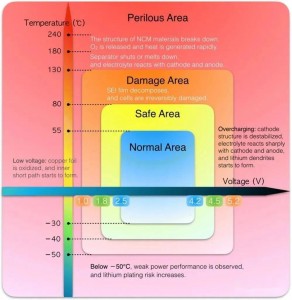

Lithium-ion battery systems are complex electrochemical and mechanical systems, and the safety of the battery pack is critical in electric vehicles. China's "Electric Vehicle Safety Requirements", which clearly states that the battery system is required to not catch fire or explode within 5 minutes after thermal runaway of the battery monomer, leaving a safe escape time for the occupants.

(1) Thermal safety of power batteries

(2) IEC 62133 standard

(3) UN/DOT 38.3

(4) IEC 62619

IEC 62619 (Safety Standard for Secondary Lithium Batteries and Battery Packs), the standard specifies the safety requirements for batteries in electronic and other industrial applications. The test requirements apply to both stationary and powered applications. Stationary applications include telecommunications, uninterruptible power supplies (UPS), electrical energy storage systems, utility switching, emergency power and similar applications. Powered applications include forklifts, golf carts, automated guided vehicles (AGVs), railroads, and ships (excluding on-road vehicles).

(5) UL 2580x

(6) Safety Requirements for Electric Vehicles (GB 18384-2020)

Post time: Jan-30-2023